In today’s world, industries and consumers alike are in constant search of materials that offer durability without adding weight. The challenge to find such materials has led to the development of micro cellular rubber. This specialized rubber is changing the landscape across a multitude of industries. From automotive to sports equipment, it provides the ideal solution for manufacturers seeking strength, flexibility, and lightness in one product.

What is Micro Cellular Rubber?

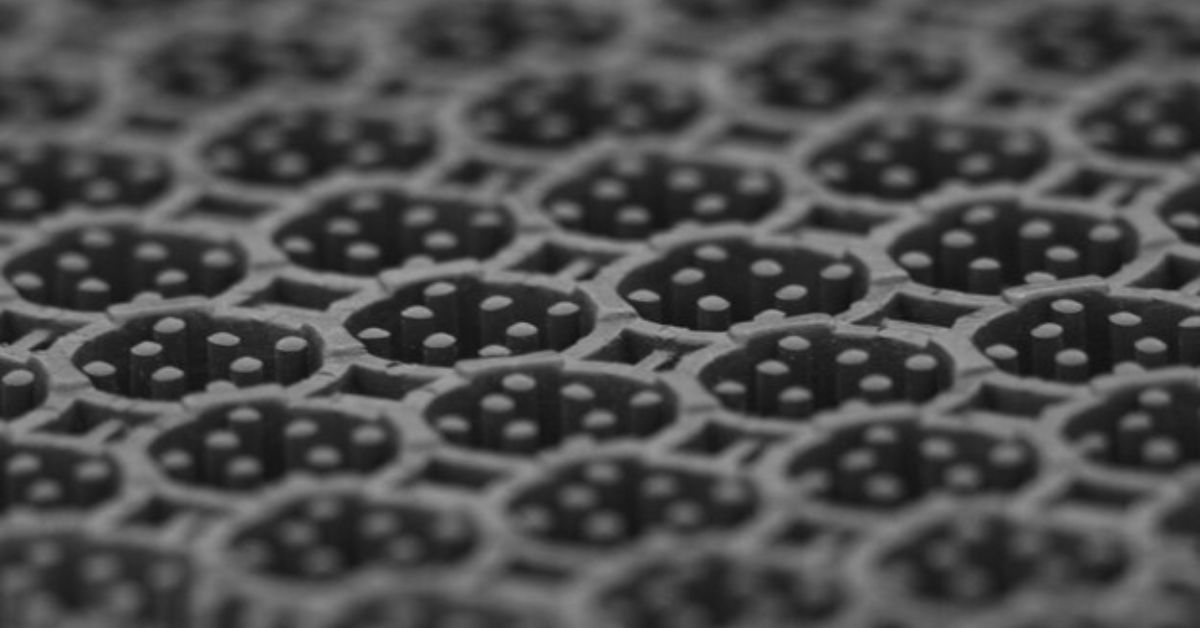

Micro cellular rubber, often referred to as MCR, is a lightweight, closed-cell foam material that has unique properties. Its structure consists of tiny cells or pockets of gas, trapped within the rubber matrix. These microscopic cells give the material its distinct lightweight and elastic qualities. The process of creating MCR involves expanding a rubber mixture during manufacturing, leading to its foamy texture.

The properties of MCR make it highly adaptable across various industries. Its ability to be strong and elastic, yet light in weight, makes it a go-to material for applications that require shock absorption, sealing, and insulation.

Key Properties of MCR

One of the main reasons micro cellular rubber stands out from other materials is its combination of useful properties. These include:

- Lightweight Nature: The foam structure of MCR makes it significantly lighter than solid rubber materials. This is advantageous in industries such as automotive and aerospace, where reducing weight can lead to better fuel efficiency and overall performance.

- Durability and Strength: Despite its lightness, MCR is incredibly durable. Its ability to withstand wear and tear makes it suitable for products that are exposed to high levels of friction and stress, such as seals, gaskets, and insulation in machinery.

- Shock Absorption: The cellular structure within micro cellular rubber makes it an excellent material for shock absorption. Its flexibility allows it to absorb energy from impacts, reducing damage to surrounding structures. This property makes it useful in products such as footwear, protective gear, and even vibration dampening in electronics.

- Resistant to Weather and Chemicals: Micro cellular rubber is resistant to a wide range of environmental conditions, including exposure to UV light, ozone, and chemicals. This resistance ensures a longer lifespan, even in harsh environments, making it ideal for outdoor applications.

- Water and Moisture Resistance: As a closed-cell material, micro cellular rubber resists water absorption. This makes it ideal for sealing applications, particularly in the automotive and construction sectors, where preventing water ingress is essential.

Industries Benefiting from Micro Cellular Rubber

Due to its versatile properties, micro cellular rubber has found applications in various industries. Some of the most prominent sectors that benefit from this material include:

1. Automotive Industry

In the automotive sector, reducing weight is a key goal for manufacturers, as it leads to improved fuel efficiency and performance. Micro cellular rubber is used extensively in vehicle interiors, door seals, and weatherstrips. Its lightweight nature ensures that manufacturers can maintain strength and durability without adding excessive weight. Additionally, the material’s shock-absorbing capabilities make it an ideal choice for automotive components that experience constant wear and tear.

2. Electronics Industry

The electronics industry has found MCR useful for its vibration dampening properties. Sensitive electronic components require protection from shocks and vibrations to ensure long-term functionality. This rubber helps absorb vibrations, protecting components from mechanical failure. It is also used in seals and gaskets to prevent moisture and dust ingress into sensitive electronic equipment.

3. Construction and Building

In construction, MCR plays a key role in sealing and insulation. The material is used in window and door seals, ensuring that buildings remain insulated from external elements like wind, rain, and noise. Its water resistance and durability in fluctuating weather conditions make it a long-lasting solution for builders.

4. Sports and Footwear

Micro cellular rubber is becoming increasingly popular in the sports and footwear industry. The shock-absorbing capabilities of this material make it ideal for shoe soles, helping to reduce the impact on feet during movement. Its lightweight nature ensures that shoes remain comfortable for prolonged periods, without compromising on performance.

5. Aerospace Industry

In the aerospace industry, every gram of weight counts. MCR is used in aircraft interiors and seals to reduce weight without sacrificing durability. The material’s resistance to temperature fluctuations and its ability to maintain performance in extreme conditions make it ideal for aerospace applications.

Advantages Over Traditional Materials

Compared to traditional materials, MCR offers several key advantages. It is more lightweight than solid rubber or plastic materials, making it easier to handle and transport. Its shock-absorbing properties mean that it can replace heavier and bulkier components in certain applications, leading to more efficient designs.

Moreover, the closed-cell structure of MCR provides superior water and air resistance, ensuring that seals and gaskets remain functional over long periods. This durability extends the lifespan of products, reducing the need for frequent replacements and maintenance.

Environmental Considerations

In today’s environmentally conscious world, the sustainability of materials is a crucial factor. Micro cellular rubber offers advantages in this regard as well. Its durability means that products made from this material have a longer lifespan, reducing waste. Additionally, many manufacturers are working on making MCR from eco-friendly and recycled materials, reducing its environmental impact.

The Future of MCR

The future looks promising for MCR, with continuous advancements in technology allowing for even more applications. Researchers are exploring ways to enhance its properties, making it even more lightweight, durable, and environmentally friendly. As industries continue to prioritize performance, sustainability, and cost-efficiency, MCR will likely remain a cornerstone material for many sectors.

Conclusion

Micro cellular rubber has revolutionized the way industries approach material design and functionality. Its unique blend of lightweight structure, durability, and shock absorption makes it a key player in modern manufacturing. Whether it’s in cars, electronics, or sports equipment, the benefits of micro cellular rubber are evident, and its potential for future growth is limitless.